NEWSLETTER

Sign up for GMORS latest news.

In the fiercely competitive market environment, the demands for quality and efficiency are increasing across various industries. As a critical component in sealing systems, precision O-Rings have a direct impact on the efficiency and quality of industries due to their precise control over dimensional tolerances and flash. Furthermore, they can add value to products across various industries.

For example:

In industrial manufacturing processes, many mechanical equipment require O-Rings for sealing, such as hydraulic and pneumatic components. Precision O-Rings effectively prevent leaks in hydraulic or pneumatic systems, especially under extreme conditions like high pressure, high temperature and high speed. Precise control over dimensions and flash is crucial, as the application of precision O-Rings directly affects the stability, efficiency and lifespan of mechanical equipment.

In the automotive industry, precision O-Rings ensure the reliability and durability of seals, thus enhancing vehicle performance and safety. Particularly in engine and hydraulic systems, the accuracy of dimensions and flash directly impacts the operational efficiency and fuel utilization of automobiles.

In the medical device field, precision O-Rings are commonly used in high-pressure gas and liquid sealing applications such as surgical instruments and medical gas supply systems. Excessive flash can pose a risk of contamination to the human body. Dimensional accuracy is a key factor in ensuring the efficient operation of instruments and patient safety.

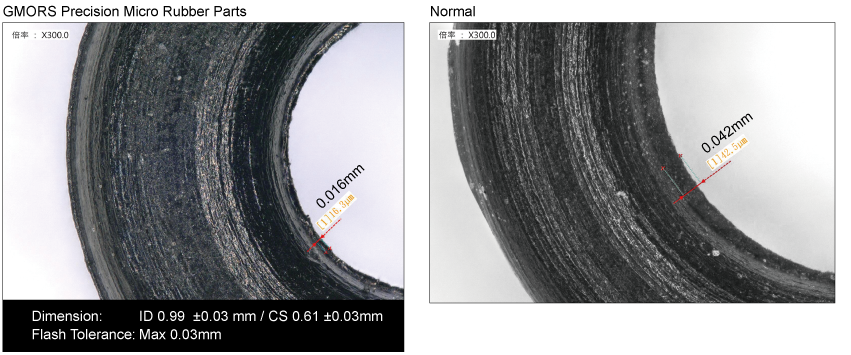

GMORS has achieved breakthroughs in the field of precision O-Ring technology with its outstanding technical strength and quality service. GMORS' precision O-Ring technology can achieve a minimum production size of an internal diameter (ID) of 0.50mm and a cross section (C/S) of 0.40mm, with dimensional tolerances controlled within ±0.01mm and flash controlled within 0.03mm. This demonstrates a high degree of manufacturing precision. (Figure 1)

GMORS primarily utilizes high-precision machine tools imported from Germany to accurately control deviations within 0.01mm during mold processing in the mold development process. It achieves precise material shrinkage control within a 1% error tolerance and ensures product dimensional stability through standardized production processes. GMORS also employs special flash removal processes and rigorous quality control through reliable AOI machine vision inspection equipment.

The precision O-Rings provided by GMORS offer excellent solutions for various industries. If you have a need for precision O-Rings, please feel free to contact us. GMORS is dedicated to providing you with the highest quality products and solutions.

Sign up for GMORS latest news.

Copyright ©GE MAO RUBBER INDUSTRIAL CO., LTD. All rights reservedTerms and Conditions|Privacy policy